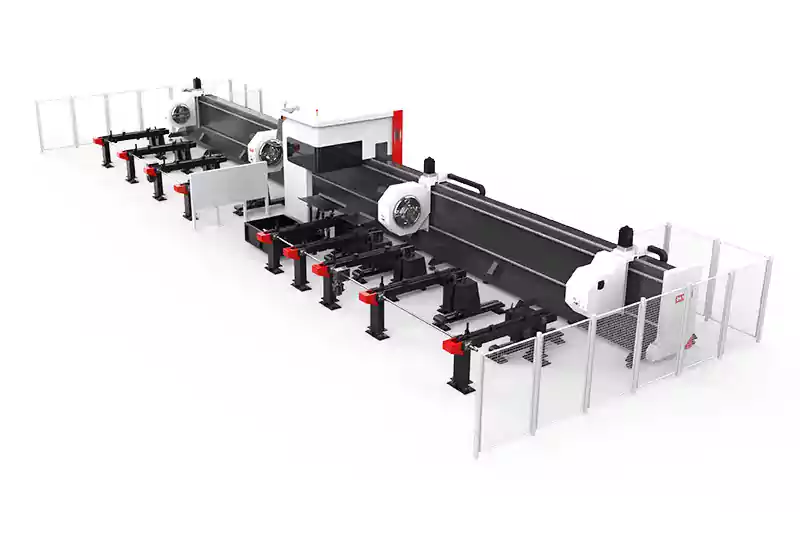

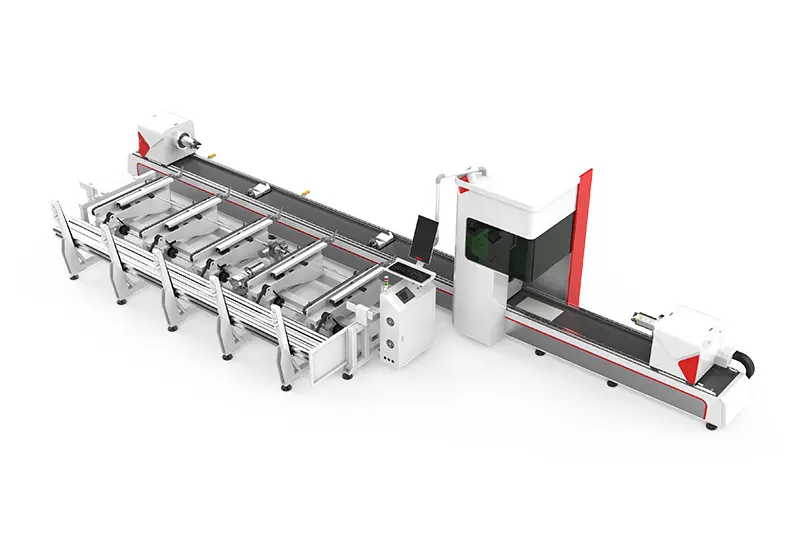

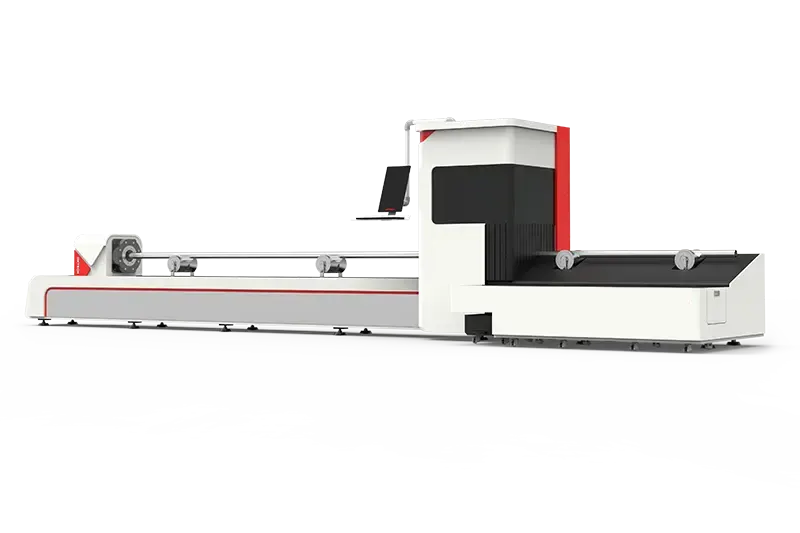

TK-Series Double Chuck Metal Tube Cutting Machine with Automatic Feeding

Specifically designed for high volume cutting of tubes and pipes provide far greater efficiency than normal laser systems when cutting pipes and tubular metals.Tube and rectangular tube can finish full automatic feeding without human operation. Deformed tubes can achieve artificial semi-automatic feeding. The fast corner response improves cutting efficiency greatly. The workpieces can be unloaded automatically in different areas after cutting.

- Only pipes can be cut, the longest can be cut to 12m, the maximum can be clamped to 350mm, and the standard matching software is widely applicable

- Divided into dual-card/three-card/four-card bevels, with rich choices

- It can be equipped with automatic loading and unloading to realize automation

This MAMTECHNIC metal tube laser cutter can process a variety of metal pipes and tubes, including round tubes, square tubes and special-shaped tubes or pipes. It can do hole cutting, beveling, grooving, vertical cutting, carving on metal tubes with high precision and efficiency. This metal tube laser cutter is widely used in automobile exhaust pipes, water pipes, oil pipes, fitness equipment, medical bed, bicycle frames, electric bicycle frames, baby carriages, kitchen storage racks, kitchenware, etc.

Advantages

- With the excellent metal pipe clamping system, the machine can stably deliver metal pipes and manufacture high-quality and high-precision products. And itcan be equipped with a slag removal device for the inner wall of the pipe.

- With the world-class Raycus/Max laser source adopted, the machine releases high-quality laser beam and processes materials precisely. The cutting edge is flat and smooth without any burrs.

- Manufactured with aerospace aluminum gantry, this machine has high processing precision, good toughness and high processing speed.

- The machine can perform various 3D processing effects on metal pipes, such as hole cutting, arc cutting, carving, slotting, etc. And it can deal with various special-shaped metal tubes, such as rectangular tubes, oval tubes, square tubes, round tubes, triangular tubes, D-shaped tubes and hexagonal tubes.

- Auto-feeding and automatic uploading ,Fast and high quality cutting ,better quality and are trustworthy,Higher accuracy in any sides, Best aftersales service

We warmly welcome domestic and overseas customers to visit our factories and offices and talk about business in person. We now have one workshop with an area of 45,000㎡ in Jinan and one factory with an area of 30,000㎡ under construction in Taian, Shandong Province.

Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

Components of Metal Tube Fiber Laser Cutter

1) Cooling: both the collimating lens and the focusing lens group are cooling accessories. Besides, the cooling airflow nozzle is added, which effectively protects the nozzle and the ceramics and prolongs the working time.

2) Chasing aperture: through the 35 mm aperture, the interference of stray light is effectively reduced.

3) Autofocus: without human interference, the focusing speed can reach 10m/min, and the repeatability is about 50 microns.

1) It is a professional tube cutting system, which can realize automatic centering and eccentric compensation of metal pipes to ensure cutting accuracy.

2) Common edge cutting: it can reduce the residual material and save the production cost.

3) Corner cutting process: the corners are not burnt, and the section quality is good.

FAQ

stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, pickled plate, copper, silver, gold, titanium and other metal plates and pipes.

Fiber laser, stepper motor, servo motor, bed, laser head, water chiller, control system, etc.

Protective lenses, nozzles, ceramic rings.

The shape of the laser beam, the width of the slit, the accuracy of the table, and the material of the work piece.

TL-Affordable 2kw Fiber Laser Tube Cutting Machine For Sale

TL-Affordable 2kw Fiber Laser Tube Cutting Machine For Sale

3D Bevel Professional Tube Fiber Laser Cutting Machine

3D Bevel Professional Tube Fiber Laser Cutting Machine

TG-Series Bevel Tube Laser Cutting Machine

TG-Series Bevel Tube Laser Cutting Machine

TM-Series Three Chuck Metal Tube Cutting Machine with Automatic Feeding

TM-Series Three Chuck Metal Tube Cutting Machine with Automatic Feeding

TK-Series Double Chuck Metal Tube Cutting Machine with Automatic Feeding

TK-Series Double Chuck Metal Tube Cutting Machine with Automatic Feeding

Economical Metal Tube Fiber Laser Cutting Machine

Economical Metal Tube Fiber Laser Cutting Machine