We are a comprehensive enterprise integrating R&D, production and sales. MAMTECHNIC has more than 10 years of experience to manufacture advanced CNC laser machines, such as the CNC laser cutting machine, laser engraving machine, and laser marking machine.

We provide the advanced CNC laser cutting machine including the fiber laser cutting machine and CO2 laser cutting machine. Our laser engraving machine and laser marking machine are very professional to process on metal or non-metal materials. Nowadays, our laser cutter, engraver, and marker are loved by the home and abroad, and more than 60 countries and regions import our laser machines.We are committed to providing integrated laser applications to users around the world.

MAMTECHNIC is a prfessional laser manufacturer providing comprehensive laser service. We help customers create their own laser cutting design, provide laser service online. No matter how to choose laser cutter, how to operate, maintain the laser machine, or any related questions before and after sale, we will solve your problems by a professional team.

With strong company strength, high-quality products, perfect after-sales service, and diversified product types,

MAMTECHNICnology has won the favor of domestic and foreign customers. Below are customers from different countries.

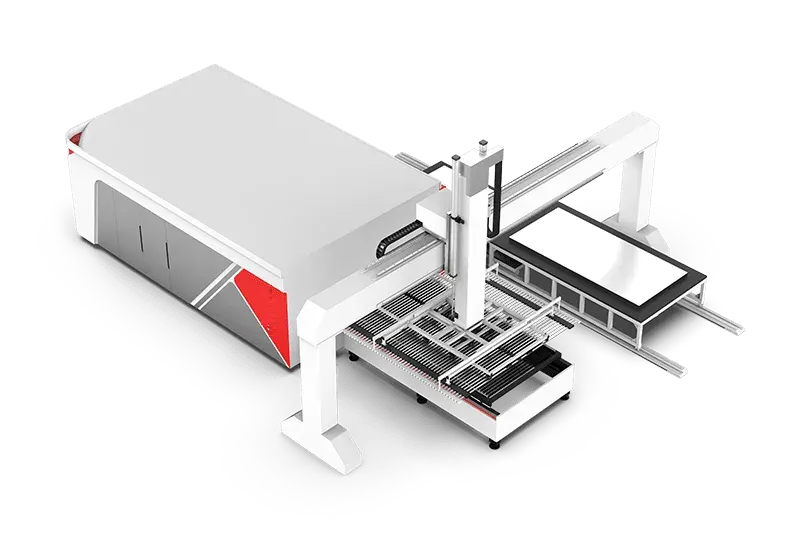

MAMTECHNIC is one of the professional CNC laser cutting machine manufacturers in China who has high-end laser cutting machine for steel plate. Our CNC industrial laser cutter takes advanced laser cutting technology and user-friend control system, also has an affordable industrial laser cutting machine price.

What is the process of buying a laser machine of MAMTECHNIC? The process of purchasing MAMTECHNIC laser machine is mainly divided into the following steps.

Customer inquiry:

The customers may get to know our company through the company website, Youtube or Alibaba, and inquire us about the machine. Both parties conduct technical and commercial communication on the laser machines. And then the sales manager recommends appropriate machines based on customer’s processing needs and budget.

Quotation

After confirming the laser machine, the sales manager of the company quote the customer. The quotation mainly includes: machine parts, specifications, whether the laser machine has special packaging requirements, the quantity of machine, the requirements for delivery time, and the transportation method of the machine, etc.

The commonly used quotation methods are: FOB (Free on Board), CFR (Cost and Freight), CIF (Cost, Insurance and Freight) and DUU (Delivered Duty Unpaid) and others. The sales managers reply to customers timely, communicate and confirm with customers about the product name, model, specifications, quantity, expected delivery term, payment terms, packaging, and sends the final confirmed quotation.

Confirm the Purchase Order or Contract

After both parties reached an agreement on the quotation, the buyer discusses with the seller formally or further on technical and commercial terms. After both parties negotiate and agree, they need to confirm the Purchase Order (hereinafter referred to as PO) or sign a contract.

In this process, the main contents include the name of the product, technical specifications and models, quantity, price, packaging, place of origin, delivery date, payment terms, after sales. Generally, the payment terms are 30% down payment and 70% paid before the shipment. The methods of making payment include the online bank transfer, T/T, Alibaba Credit Insurance (supporting credit card payment). And sometimes, we also accept the the Letter of Credit (L/C). Both parties will write the agreement reached after discussion into the PO or the contract.

Customers pay the down payment

After receiving the PO, we will send the Proforma Invoice to the customer. After receiving the Proforma Invoice, the customer can pay the down payment through the agreed payment method.

Production arrangement

After receiving the 30% down payment, we start to produce the laser machine as required according to the machine specifications confirmed on the Purchase Order. Progress photos will be provided to customers during production.

Machine production completed

After the machine is manufactured completely and passes the factory test, we will send the pictures of the whole machine to the customer. If everything is OK, the customer pays the balance, and we confirms and arranges the delivery with the customer.

Packaging and delivery.

The photos of the packaging and delivery process can also be taken to provide customers, in order to keep customers updated about the latest status of the laser machines.

Transportation, and receival of laser machine.

After receiving the laser machine, the customers can give us feedback on the status of the goods when they are received, the operation of the laser machine, and so on. Furthermore, if any problems, we will also have dedicated after-sales personnel standby to provide technical support to customers.

We are welcome any feedback about our industrial laser cutting machine when you receive it. Any comment you leave might help us become more perfect as a CNC laser cutting machine manufacturer.

MAMTECHNIC, as the advanced CNC laser machine manufacturer, mainly manufactures and supplies the laser cutting machines, laser welding machines, laser engraving machines and laser marking machines. Their functions and applicable materials are briefly introduced at below.

MAMTECHNIC is not only a professional CNC laser cutting machine manufacturer, but also an excellent laser engraving and welding machine manufacturers. We also provide laser welding machine and laser engraving machine.

Laser cutting machine

The laser cutting machine of MAMTECHNIC is to use the high-density energy released when the laser beam irradiates the surface of the work-piece to melt and evaporate the work-piece to achieve the purpose of cutting. It has high precision, fast cutting speed and smooth cutting edges, not limited to cutting patterns.

As a one of the professional fiber laser cutting machine manufacturers in China, our advanced industrial laser cutting machine can cut nearly all kinds of metal materials.

According to different laser sources, MAMTECHNIC’s industrial laser cutting machines are mainly divided into CO2 laser cutting machine and fiber laser cutting machine.

CO2 laser cutting machine is used for cutting non-metal materials, for example, acrylic materials, wood, leather, cloth, plastic and paper.

Fiber laser cutting machine also known as laser cutting machine for steel plate, is mostly used to cut metal materials, such as, carbon steel, stainless steel, alloy steel and galvanized sheets, etc.

Laser welding machine

The laser welding machine of MAMTECHNIC is also one of the important laser machines. The working principle of this machine is to use the pulse laser for welding. After beam expanding, reflection and focusing, the laser beam radiates on the surface of the work-piece. The surface heat diffuses to the internal through heat transfer. And the work-piece begins melting to form a specific molten pool. In this way, the laser welding machine completes the precision welding. The laser beam welding has the unique advantages of smooth welding seam, small focus spot, and high positioning accuracy.

The laser welding machine is suitable for welding the same metal materials, such as stainless steel, gold, silver, and alloy. And it is also applicable for welding many kinds of dissimilar metal materials. For example, the laser welder can weld copper and nickel, nickel and titanium, low-carbon steel and copper.

It is applicable to the electronic components, precision machinery, communications, and other industries. There are also many users in the phone batteries, sensors, medical devices, craft gifts, and clocks processing industries.

Laser engraving machine

The laser engraving machine of MAMTECHNIC is the equipment that uses the thermal energy of laser to engrave the suitable materials. And this machine uses laser beams to engrave permanent marks on the surface of various materials. The materials melt and vaporize physically under the laser engraving irradiation, resulting in engraving marks. As it is non-contact processing, the laser engraving machine will not cause mechanical deformation or damage on the work-piece.

The laser engraving machines can be divided into CO2 laser engraving machines and fiber laser engraving machines.

-CO2 laser engraving machine

Generally used for the engraving processing of non-metal materials, such as wood, acrylics, fabrics, plastics, paper and leather, etc.;

-Fiber laser engraving machine

Mainly for engraving most of metal materials, such as stainless steel, carbon steel, silicon steel, alloy steel and galvanized plates, etc;

Laser marking machine

The laser marking machine of MAMTECHNIC uses a laser beam to make permanent marks on the surface of various materials. Laser marking is the process of using laser energy to evaporate the surface material to expose the deep material, thereby marking exquisite patterns, trademarks and letters on work-piece.

Laser marking machine is mainly divided into CO2 laser marking machine, fiber laser marking machine, and UV laser marking machine.

– CO2 laser marking machine is the marking equipment using carbon dioxide laser technology for marking non-metallic materials mostly. For example, the materials for CO2 laser marking include wood, paper, epoxy resin, acrylic, leather, glass, ceramics, and rubber, etc.

– The fiber laser marking machine uses fiber as the working medium. And it can be mainly used to mark stainless steel, aluminum, carbon steel, and many other metal materials, as well as some non-metallic materials.

– And the UV laser marking machine uses the ultraviolet laser of the clod light source. It is mainly used in the high-end market of ultra-fine processing. The machine can mark on the surface of packaging bottles of pharmaceuticals, cosmetics, and other polymer materials, with very precise effect.

MAMTECHNIC as an independent laser brand of Blue Elephant, is a comprehensive enterprise integrating R&D, production and sales. We are a laser cutting machine manufacturer with more than 10 years of experience to provide advanced CNC laser steel cutting machines. Our industrial laser cutting machine can deal with various kind of metal and non-metal. Cooperate with MAMTECHNIC you will have a high-end CNC laser cutting machine with an affordable industrial laaser cutting machine price.

There are some reasons why you choose MAMTECHNIC:

Professional Team

MAMTECHNIC has a team of more than 200 employees, including an after-sales service team of 40 staff, and exported to more than 130 countries such as Europe and the United States, serving more than 7,000 manufacturing companies around the world up to now.

Product Advantages

With excellent mechanical manufacturing and assembly technology and strict quality control, MAMTECHNIC provides customized solutions according to exact demands of customers. Some outsourcing parts of MAMTECHNIC laser machines, such as electrical devices, are from world-renowned brands.

All the laser machines are made and flexibly configured according to customer needs and the characteristics of laser machine itself. Under the premise of ensuring the performance of laser machine, it can greatly save costs for customers and provide lager profit space for enterprise users. With many years of laser machine manufacturing and sales experience, we understand the real needs of customers.

MAMTECHNIC owns the advanced manufacturing equipment, continuous introduction of high-tech laser machines. And the laser cutting, engraving and marking machines made by MAMTECHNIC can be widely used in advertising, packaging, printing, textiles, glass, plastics, mechanical processing, automobiles and other industries.

Thoughtful Pre-sales and After-sales Service

Pre-sales Service

From laser machine customization to delivery, you only need to tell us your processing demands, requirements for quality and testing and budget. And we will recommend the appropriate laser machine and its configurations as soon as possible. From the solution providing, approval to design, machine manufacturing, testing and delivery, as well as the operation training, we provide customers with worry-free laser machines and service throughout the entire buying process.

After-sales Service

MAMTECHNIC owns an experienced after-sales team providing comprehensive after-sales service and technical support. MAMTECHNIC also provides the laser machine operation training, machine and daily maintenance or repair training, etc. We guarantee to immediately respond to failures and initiate after-sales emergency response mechanisms.

With the free installation training and 24-hour after-sales response mechanism, MAMTECHNIC quickly solves after-sales problems, provides the value-added services related to the laser machine, and follow-up maintenance for life.

MAMTECHNIC laser machines are widely welcomed and praised by customers for its high-quality laser machine products and sales service. It is sold all over the world, and the satisfaction of customers is the best proof.

Reasonable Price

MAMTECHNIC not only provides efficient and intelligent laser cutting, engraving and marking equipment, but also pays more attention to the actual needs of customers. Instead of recommending unnecessary parts with higher prices, we offers the reasonable selection of configurations for customers under the premise of ensuring the performance of laser machines.

System Certification

ISO9001 Quality Management System Certification; TUV Management System Certification; SGS Product Quality Technical Certification; CE certification for product quality; BV quality inspection certification.

Find advanced fiber laser cutter from a professional fiber laser cutting machine manufacturer will help you avoid lots of defects during the cutting process. We are one of the professional fiber laser cutting machine manufacturers in China who provide CNC laser steel cutting machine especially laser cutting machine for steel plate. Our machine are available of various metal plates. We have advanced CNC laser cutting steel cutting machine, laser cutting machine for steel plate, and provide an affordable industrial laser cutting machine price.

There are more and more customers who choose MAMTECHNIC all over the world, as the quality of MAMTECHNIC laser machines are stable and reliable, the price is very reasonable, and the cost performance is higher. We always insist on treating customers with our heart and continue to supply them the good-quality laser machines with higher cost performance and thoughtful services.

The cutting or engraving processing of a laser machine is to replace the traditional mechanical tool with invisible beam. It has the characteristics of high precision, fast cutting, not limited to cutting pattern limitation, and automatic operation. The laser machine saves materials, and the materials after laser processing have smooth incision, low processing cost. But we often encounter some faults when using the laser machine. In this article we will talk about the common problems and solutions in the process of using the laser machine.

There might have some problems in CNC laser steel cutting machine application. As one of the professional CNC laser cutting machine manufacturers we are ready for solving any problems of CNC laser steel cutting machine application. We provide affordable industrial laser cutting machine prices and high-quality industrial laser cutter instruction service.

1. Deformation of round holes or straight lines processed by laser

During the laser processing, the circular hole to be processed may be deformed and twisted. And some users may encounter that the straight line becomes a wavy line.

When this kind of problem occurs, we should first check whether the laser cutting control software is operating normally. For example, the users can draw a straight line to observe whether the laser head is moving in a straight line during processing. This can basically confirm the possibility of software problems. At the same time, this step can also find abnormal problems of the loosening of the mechanical structure.

After eliminating the possibilities of software and mechanical faults, we should think about whether the laser energy is too high. And the non-processing area is affected by the over high energy. We can observe whether the cutting edge of the work-piece is melting. The normal processing edge should be smooth and flat. In case of any melting, we should appropriately lower down the laser power or frequency parameters to solve the problem. There is also a relatively uncommon possibility. The deformation of the focusing lens in the laser head can also cause such problems. It can be judged by observing whether the beam from the laser head is concentric or not. If not, it needs to change the focusing lens.

2. Incomplete penetration in the process of laser processing

Such problem is very common in laser cutting machines, and the causes of problems are also varied. The laser cutting is a processing method in which the material is blown off while melting. So we can analyze whether it is not melted or not blown off.

First, analyze the situation of not melting. The reasons for not melting are generally insufficient power, and dirt on the focusing lens blocking the laser beam, etc. If the power is not enough, it can be increased by modifying the parameters on the laser cutting software. High-power laser controllers will have the problem of power attenuation during long-term use. Therefore, when purchasing the laser cutting machine, it is better to choose the one with enough power on the basis of meeting processing requirements.

If the problem is that there is something dirty on the lens, we can take out the lens to check. After confirming that the problem caused by the dirt, we can solve it by replacing or cleaning the lens. Please note that only use absorbent cotton or special lens cleaning paper dipped with absolute ethanol to clean the lens. It is strictly forbidden to touch the lens with hands or other objects to avoid damage to the lens coating.

The work-piece has burr when using laser cutting machine

First of all, check if it is because of the problem of lens focusing. If the laser focus position is not correct, you can adjust the focus to solve this problem.

Secondly, check whether the laser is normal. On the premise of confirming the normal operation of the laser, further check whether the output power of the laser matches the power required. If not, it needs to be adjusted.

Cutting speed problem: the cutting speed is too slow and will also cause burr at the bottom of the cutting surface. At this time, it is necessary to speed up the cutting speed.

Gas problem: the purity of the auxiliary gas can also affect the quality of cutting. When the purity of the gas is not enough, the problem of causing burr will occur. It is necessary to replace the gas with higher purity for cutting.

Abnormal spark occurs during the laser processing

If there is abnormal spark during the laser processing, it will affect the degree of quality at the cutting and engraving surface. At this moment, under the condition that other parameters are normal, the users can consider the following conditions. If it is because the loss of laser nozzle, the new nozzle should be replaced in time. In the case of no need for replacing new nozzle, the cutting gas pressure should be increased. It also needs to check whether the screw at the joint of nozzle and laser head becomes loose, and tighten the screw thread.