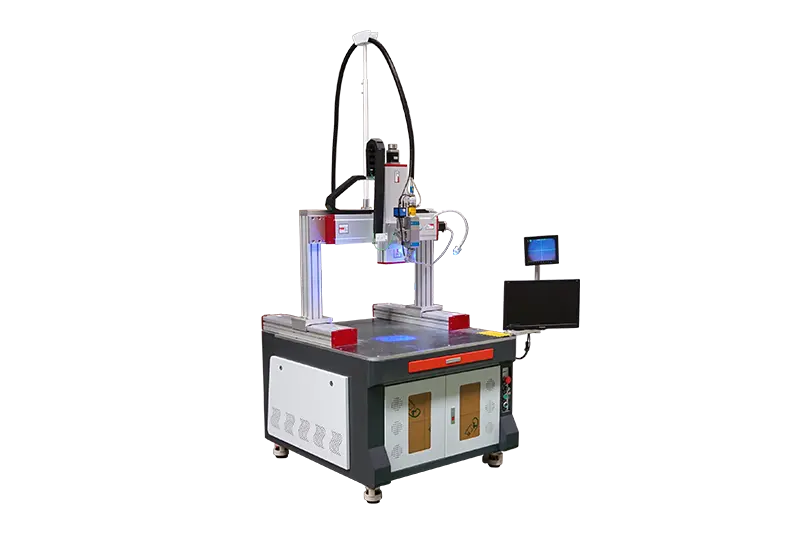

2kw High Efficiency Galvo Laser Welding Machine for The Electronics Industry

MAMTECHNIC galvo laser welding machine adopts the mirror galvanometer scanning method, which realizes the laser spot’s rapid movement through the mirror galvanometer’s swing. It can realize high-speed and high-precision spot welding and continuous welding of any pattern on the welding plane within the welding range. , therefore compared with the traditional automatic welding machine that moves the workpiece for welding through stepper servo motor transmission, the welding speed is greatly improved. It has the advantages of fast welding speed, high precision, stable quality, convenient operation, and simple maintenance. It is especially suitable for laser precision spot welding of various parts.

- Laser power : 1500W, 2000W

- The welding speed is fast, the welding spot is small, the welding heat is small, and the thermal deformation is small.

- The welding quality is very stable, the welds are beautiful, and no subsequent processing is required.

MAMTECHNIC galvo laser welding machine uses self-developed laser welding software, and the welding seams are fine and beautiful; the galvanometer system uses high-quality galvanometers to perform single-point welding faster than traditional XY-axis platforms; it is widely used in mobile phones, computers, and microelectronic components, precision parts, intelligent terminal product components and other industries, and various metal materials. It has fast welding speed, high precision, and good beam pattern, and is especially suitable for laser precision spot welding of various parts.

ADVANTAGES

1. It can not only weld thin plates but also thick plates. The welding quality is very stable, the welds are beautiful, and no subsequent processing is required.

2. The high-speed moving scanning lens is used instead of the two-dimensional workbench, and the software with powerful graphics processing functions is used to realize program-controlled instant multi-point welding, effectively improving production efficiency and flexibility.

3. The welding speed is fast, the welding spot is small (the spot diameter at the focus is only 0.3mm), the welding heat is small, and the thermal deformation is small.

4. The light guide system of the product enables laser spot welding to be performed effectively and stably through the rapid movement of the galvanometer.

5. According to different welding materials, the output energy waveform can be set and waveform controlled to achieve a more ideal welding effect.

6. With fast welding speed and high production efficiency, it can greatly shorten the welding cycle and improve production efficiency.

WELDING PARAMETERS

| Model | MAMTECHNIC galvo laser welding machine |

| Laser power | 1500W, optional: 1000W, 2000W |

| Laser | MAX |

| Galvanometer | HP20-3000 high power galvanometer |

| Working area | 220x220mm |

| Voltage | 380V, 50HZ, 3P |

| Cooling method | S&A water chiller |

| Welding material | Aluminum, nickel, copper |

APPLICATION

MAMTECHNIC galvo laser welding machine is widely used in mobile phones, computers, microelectronic components, precision parts, intelligent terminal product parts, and other industries. It is mainly used for laser welding between carbon steel, ordinary alloy steel, stainless steel, and different steel materials.

MAMTECHNIC 6KW Automatic 6 Axia Laser Welding Robot for Sale

MAMTECHNIC 6KW Automatic 6 Axia Laser Welding Robot for Sale

1500W Handheld 4 in 1 Laser Welding Machine with Chaoqiang SUP23T Welding Gun

1500W Handheld 4 in 1 Laser Welding Machine with Chaoqiang SUP23T Welding Gun

1500W Mini Portable Handheld “4 in 1” Fiber Laser Welding Machine

1500W Mini Portable Handheld “4 in 1” Fiber Laser Welding Machine

2kw High Efficiency Galvo Laser Welding Machine for The Electronics Industry

2kw High Efficiency Galvo Laser Welding Machine for The Electronics Industry

Automatic laser welding machine for stainless steel processing

Automatic laser welding machine for stainless steel processing

Handheld “4 in 1” Fiber Laser Welding Machine

Handheld “4 in 1” Fiber Laser Welding Machine

Portable Mini Handheld Fiber Laser Welding Machine

Portable Mini Handheld Fiber Laser Welding Machine

Three-in-One Machine for Welding, Cleaning and Cutting

Three-in-One Machine for Welding, Cleaning and Cutting

3D Automatic Fiber Laser Welding Machine

3D Automatic Fiber Laser Welding Machine

Hot Sale Handheld Fiber Laser Welding Machine for Metal Welding

Hot Sale Handheld Fiber Laser Welding Machine for Metal Welding

Fast Speed Automatic Laser Welding Machine

Fast Speed Automatic Laser Welding Machine

Automatic Laser Welding Machine

Automatic Laser Welding Machine