How to Choose A Fiber Laser Cutting Machine for Metal?

Now fiber laser cutting machines for metal plays an important role in many enterprises. As long as enterprises cut metal, sheet metal, steel, and other consumables, there will be a fiber laser cutting machine for metal. Many companies want to use laser cutting equipment to improve production efficiency. But many companies don’t know how to choose a fiber laser cutting machine for metal. Let me introduce how to choose a fiber laser cutting machine for metal:

CHOOSE THE POWER OF THE MACHINE

When choosing the power of the fiber laser cutting machine for metal, we should fully consider the thickness of the frequently processed materials. For example, most factories cut metal sheets below 6mm. At this time, a 500W fiber laser cutting machine can meet production needs. If the production is large, buyers can purchase two or more small and medium power laser cutting machines. In this way, it is helpful for manufacturers to control costs and improve efficiency.

CHOOSE THE TYPE OF THE MACHINE

When choosing a metal laser cutting machine, you should also confirm whether you want to cut sheets, pipes, or both. If you are only cutting sheets, then choose a sheet laser cutter. If you’re only cutting tubing, then choose a tubing laser cutter. If you are going to cut sheet metal and tube at the same time, we recommend a plate and tube laser cutter.

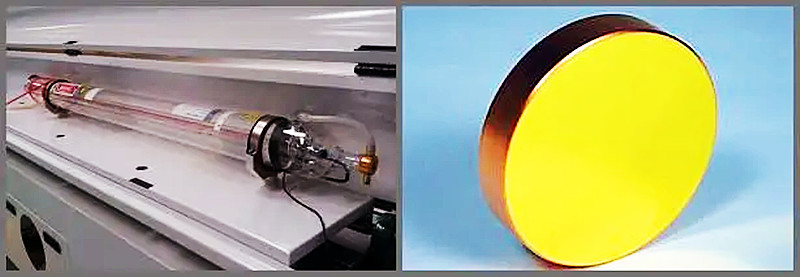

CHOOSE THE ACCESSORIES FOR THE MACHINE

The quality of the fiber laser cutting machine for metal is related to the accessories. In addition to the main accessory of the laser, accessories such as a laser cutting head, servo motor, guide rail, and water tank are very important. These parts will directly affect the cutting speed and precision of the CNC laser cutting machine. So try to choose a good brand when choosing these accessories.

CHOOSE THE AFTER-SALES SERVICE OF THE MACHINE

Even if the fiber metal laser cutting machine is easy to use, the operator will encounter various problems when using it. When a problem arises, it is important whether the manufacturer can provide a solution in time. Time is money. One more day of delay in equipment failure will result in one more day of loss.

CONCLUSION

To sum up, choosing a suitable fiber laser cutting machine for metal needs to consider the above aspects. Buyers can consult the manufacturer to understand the detailed parameters of the machine before choosing. Choosing the right equipment can improve production efficiency and product quality.

In recent years, the laser equipment industry has developed rapidly. We know that only by continuously improving product quality can we meet customer’s requirements. MAMTECHNIC will provide customers with high-quality services so that every customer can feel our sincerity.