CO2 Laser Cutting Problems And Solutions

In the use of laser cutting machines, there are always various problems. Compared with traditional cutting technology, laser cutting has the advantages of high speed, narrow slit, and small heat-affected zone. Today, I would like to introduce CO2 laser cutting problems and solutions to you, hoping it will be useful to you.

WHY IS THE LASER GETTING SMALLER AND SMALLER?

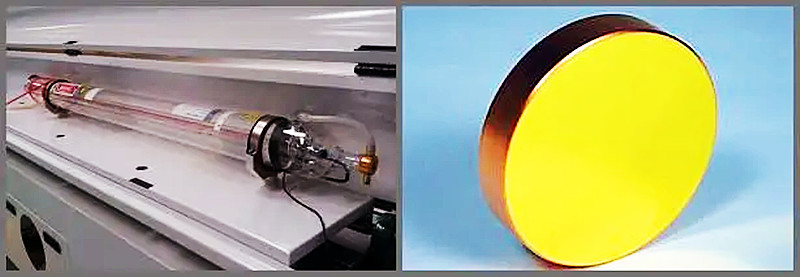

The reason why the laser of the cutting machine is getting smaller and smaller may be that the warranty period of the laser tube has passed and the service life is approaching. Because the laser tube is a consumable, the power will inevitably decline. In addition, we can check the following aspects: Does the optical path of the laser deviate? Do laser lenses need cleaning? Is the current of the laser power supply stable? Is the cutting speed too fast?

WHAT TO DO IF THE GLASS TUBE DOESN'T EMIT LIGHT?

Generally, we first observe whether the laser power supply is normally energized. In addition, we should also observe whether there is something unusual inside and outside the laser tube and whether the water circulation system is normal.

If it is not normal, we should make a corresponding replacement or adjustment. When the above aspects are normal, we should consider the optical signal problem. Generally, we should first test the laser tube and laser power supply by short-circuiting the signal. If this method can emit light normally, it means that the laser power supply of the laser tube is fault-free. This may be a signal problem with the water protection switch, relay door switch, and board PWM signal. And we just need to rule it out in turn. If this method does not emit light, it is a problem with the laser tube or laser power supply.

WHAT SHOULD I DO IF THE CUTTING EFFECT IS NOT OBVIOUS OR CAN'T BE CUT THROUGH?

First of all, there are several reasons for being impenetrable:

- Check the light outlet of the CO2laser tube. If the lens is damaged, clean it. If it is damaged, please replace the lens.

- Check whether the optical path is accurately located in the center of the lens. The adjustment of the light path can pass the point-and-shoot test. It is best for two people to coordinate the operation.

Solutions:

- Increase the working current, but it cannot exceed the tolerable range of CO2laser tube. Note: Please keep it at an appropriate current level. A higher current will shorten the service life of the laser tube.

- Reduce the size of the light spot.

3. Replace a new CO2 laser tube.

4. Adjust the support angle. Choose the best spot pattern.

CONCLUSION

The above is the CO2 laser cutting problems and solutions for your reference. As an expert in laser-cutting applications, MAMTECHNIC has fully considered the problems that customers may encounter when using laser-cutting machines. Moreover, we provide comprehensive services to solve related problems in a timely manner. Please continue to follow and support us!