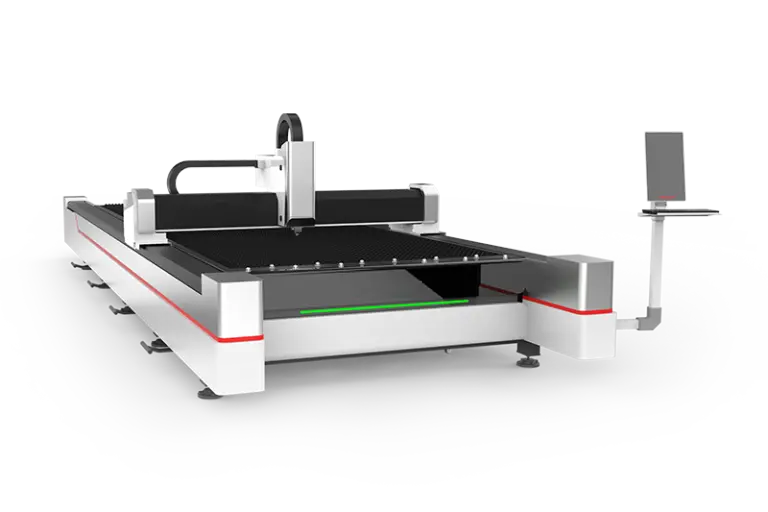

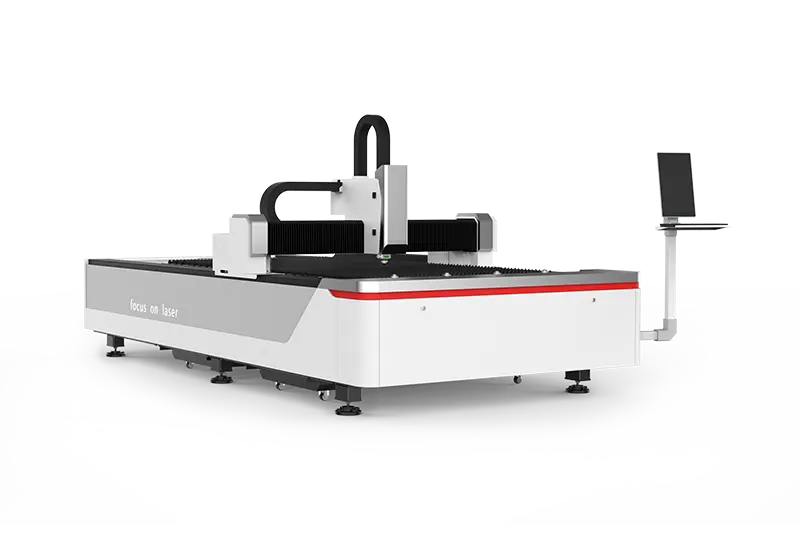

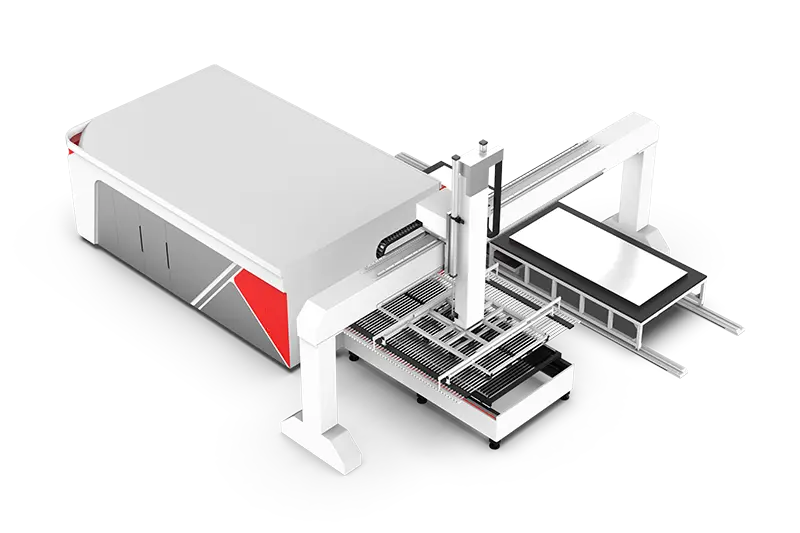

Full Cover Exchange Table Fiber Laser Cutting Machine

MAMTECHNIC SP series all cover iber laser cutting machine as one classic model, widely used in many common areas of our life, such as processing of stainless steel kitchenware, storage cabinet and other cabinets, is closely related to people’s daily life. Used for cutting a variety of metal plates, mainly used in stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass, aluminum, various alloy plate, rare metal and other metal materials.

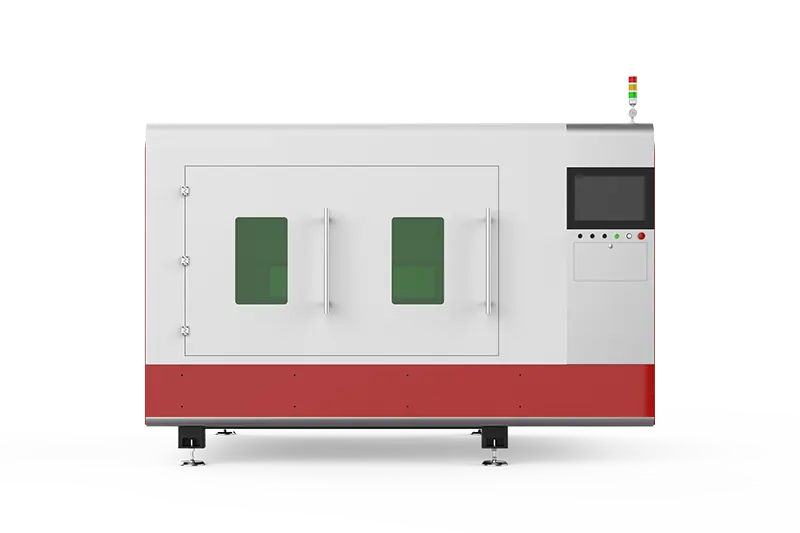

- Fully enclosed laser shield, spark prevention, eye protection, environmental protection

- 15 seconds to exchange platforms, greatly improving efficiency and saving manpower

The full-cover fiber laser cutting machine adopts a fully-enclosed laser protective cover, equipped with a special laser protective glass observation window, a scientific fume recovery and purification processing system and a standard exchange platform. The enclosure protects the operator from sparks and slag splashes during production and maintains the cleanliness of the work area. Swapping pallets allows for quick and easy loading and unloading of metal sheets with high processing efficiency. Our full hood fiber laser cutter with exchange table is the first choice for modern metal fabricators.

Advantages

- Metal sheet fiber laser cutting machine, carry Raycus/IPG/MAX power source, power 1000w, 1500w, 2000w, 3000w, 4000w, 6000w, for cutting all kinds of metal thickness from 1mm to 25mm.

- Low cost and the power consumption is 0.5-1.5kw/h; Customer can cut all kinds of metal sheets by blowing air;

- High-performance. Imported the original packaged fiber laser, with stable performance and the lifespan is over 100,000 hours;

- High speed and efficiency, the speed of cutting metal sheets close to tens of meters;

- The laser maintenance free;

- The cutting edge looks perfect and the appearance is smooth and beautiful;

- Imported the transmission mechanism and servo motor, and high cutting accuracy;

- Dedicated software enables graphic or text to be instantly designed or processed. Flexible and easy operation.

MAMTECHNIC Service

We warmly welcome domestic and overseas customers to visit our factories and offices and talk about business in person. We now have one workshop with an area of 45,000㎡ in Jinan and one factory with an area of 30,000㎡ under construction in Taian, Shandong Province.

Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

Components of Fiber Laser Cutting machine

1) Cooling: both the collimating lens and the focusing lens group are cooling accessories. Besides, the cooling airflow nozzle is added, which effectively protects the nozzle and the ceramics and prolongs the working time.

2) Chasing aperture: through the 35 mm aperture, the interference of stray light is effectively reduced.

3) Autofocus: without human interference, the focusing speed can reach 10m/min, and the repeatability is about 50 microns.

Adopting high-quality carbon plate steel welding bed, it is more stable and durable than normal tube welding bed. The high-strength machine tool adopts 600 ℃ stress relief annealing treatment, which has strong structural rigidity, small deformation, and low vibration to ensure cutting accuracy.

1) It has the characteristics of corrosion resistance, light weight, and high rigidity, which ensures high-speed movement during laser processing.

2) It has perfect dynamic performance, such as anti-distortion, anti-overturning, anti-deformation, etc., ensuring higher cutting accuracy.

Weihong laser cutting control system is a software for plane laser cutting. It supports AI, DXF, PLT and international standard G codes generated by Mater Cam, Type3, Wentai, etc.

Except common editing and typesetting functions, it has unique processing sequence browsing and powerful material database to load the specification directly. Besides, operators can control the system through wireless handheld box and Ethernet conveniently.

The Past Work

FAQ

stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, pickled plate, copper, silver, gold, titanium and other metal plates and pipes.

Fiber laser, stepper motor, servo motor, bed, laser head, water chiller, control system, etc.

Protective lenses, nozzles, ceramic rings.

The shape of the laser beam, the width of the slit, the accuracy of the table, and the material of the work piece.

1KW MQ High Precision Fiber Laser Cutting Machine Open Type

1KW MQ High Precision Fiber Laser Cutting Machine Open Type

W-Series Super Large Format Fiber Laser Cutting Machine

W-Series Super Large Format Fiber Laser Cutting Machine

FB-Series Metal Sheet Cnc Fiber Laser Cutting Machine

FB-Series Metal Sheet Cnc Fiber Laser Cutting Machine

EL-Series Fiber Laser Cutter with Exchange Platform

EL-Series Fiber Laser Cutter with Exchange Platform

EP-Series Fiber Laser Cutter with Exchange Platform

EP-Series Fiber Laser Cutter with Exchange Platform

Co2+Fiber 2 in1 Laser Cutting Machine

Co2+Fiber 2 in1 Laser Cutting Machine

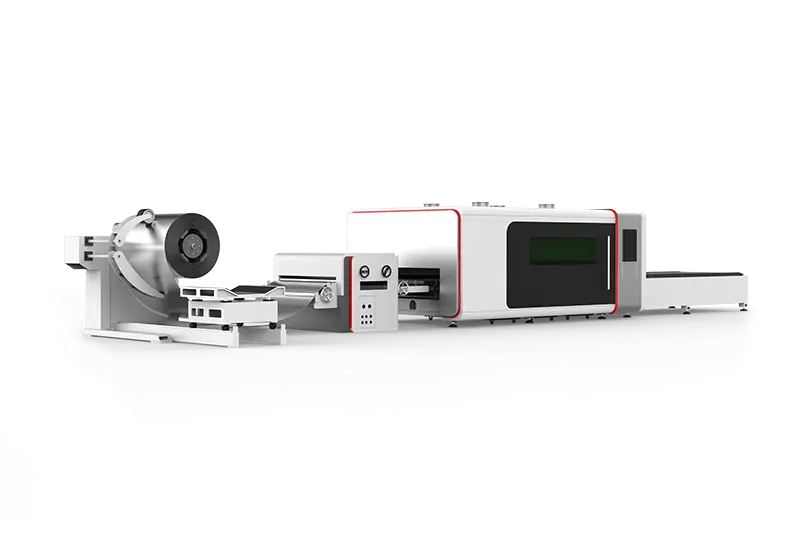

Uncoiling and Leveling Fiber Laser Cutting Machine

Uncoiling and Leveling Fiber Laser Cutting Machine

Full Cover Exchange Table Fiber Laser Cutting Machine

Full Cover Exchange Table Fiber Laser Cutting Machine

Large Format Medium and Low Power Fiber Laser Cutting Machine

Large Format Medium and Low Power Fiber Laser Cutting Machine

Mini High precision Fiber Laser Cutting Machine

Mini High precision Fiber Laser Cutting Machine

SC-Series New Automatic Metal Coil Fed Feeding Fiber Laser Cutting Machine

SC-Series New Automatic Metal Coil Fed Feeding Fiber Laser Cutting Machine

EA-Series Automatic Feeding Fiber Laser Cutting Machine with Exchange Platform

EA-Series Automatic Feeding Fiber Laser Cutting Machine with Exchange Platform

SG High Power 8kW 12kW 20kW All Cover Fiber Laser Cutting Machine with Exchange Platform

SG High Power 8kW 12kW 20kW All Cover Fiber Laser Cutting Machine with Exchange Platform

Fiber Laser Cutting Machine For Thin Material

Fiber Laser Cutting Machine For Thin Material

Ultra-precision Fiber Laser Cutting Machine

Ultra-precision Fiber Laser Cutting Machine

Medium-to-Thin Fully Automatic Loading and Unloading Laser Cutting Machine

Medium-to-Thin Fully Automatic Loading and Unloading Laser Cutting Machine

Medium-to-thick Sheet Metal Laser Cutter with Loading System

Medium-to-thick Sheet Metal Laser Cutter with Loading System

All Cover Full Automatic Loading and Unloading System

All Cover Full Automatic Loading and Unloading System

FC-Series Automatic Fiber Laser Coil Cutting Machine

FC-Series Automatic Fiber Laser Coil Cutting Machine

Q-Series High-precision Fiber Laser Cutting Machine

Q-Series High-precision Fiber Laser Cutting Machine

All Cover Exchange Table Metal Sheet Laser Cutter

All Cover Exchange Table Metal Sheet Laser Cutter

FP-Series Economical Metal Sheet Laser Cutting Machine

FP-Series Economical Metal Sheet Laser Cutting Machine