What Gas Does Fiber Laser Metal Cutting Machine Use?

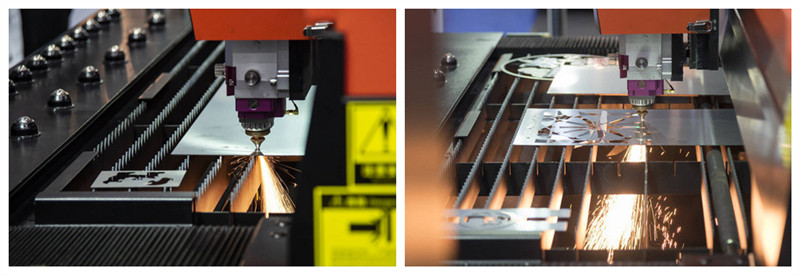

Metal laser cutting machine has higher requirements for gas. Gas can help the laser cutting machine blow off the residue during cutting. In this way, it is not easy to appear slag hanging at the cutting section, which ensures the cutting effect. The gas used in laser cutting machines mainly includes oxygen, nitrogen, air, and Argon. So, why do we use gas and how to choose gas?

WHY GAS IS USED IN FIBER LASER METAL CUTTING MACHINES?

Laser cuts a lot of calories. High heat concentration will burn the material in the cutting area. And it is also easy to deform the processing parts. Therefore, we need to add some auxiliary gases.

HOW TO CHOOSE WHICH GAS TO USE FOR THE LASER CUTTING MACHINE?

- When we process stainless steel, we should choose nitrogen. Nitrogen prevents oxidation of the cut. In this way, the processed incision will not have blackening. When choosing nitrogen, we should choose high-purity gas.

- If you are processing carbon steel plates, you must choose oxygen. Oxygen mainly plays a role in supporting combustion, which can speed up the processing speed of the workpiece. Of course, the purity of oxygen should be as high as possible.

- In some requirements that are not very precise, we can also choose oxygen. Because the cost of oxygen use is low, it also has a great auxiliary effect.

It should be noted that whether the laser cutting machine uses air, oxygen, or nitrogen, there are air pressure requirements. Fiber laser metal cutting machines have high requirements. Generally, it cannot cut through or hang slag because the purity of the gas is not up to standard or the gas is insufficient. Therefore, the selection and use of auxiliary gas play a very important role in cutting.

CONCLUSION

To sum up, the auxiliary gases of laser cutting machines usually include oxygen, air, and nitrogen. Different auxiliary gases are used to cut different materials. According to the thickness of the cutting material, the pressure and flow rate of the auxiliary gas are different. Therefore, the pressure of the auxiliary gas has a direct impact on the laser cutting effect. In order to find the gas suitable for his own model, the operator has to consider many factors such as equipment power, cutting materials, and cutting costs.

Thanks to all users for their feedback. Because of everyone’s support, we have become what we are today. MAMTECHNIC will try to make you satisfied! With your support, we will do better! Our factory can provide you with high-quality products to meet your processing needs.