The Difference Between CNC Routers And Laser Cut Machines

Nowadays, with the rapid upgrading of products, the market has put forward higher requirements for the flexibility of processing equipment. But in the whole processing market, laser cut machines and numerical control machines are both favored by manufacturers. This article will introduce laser cut machines and CNC machines. CNC Routers and laser cut machines are two different cutting tools. They differ in the following aspects:

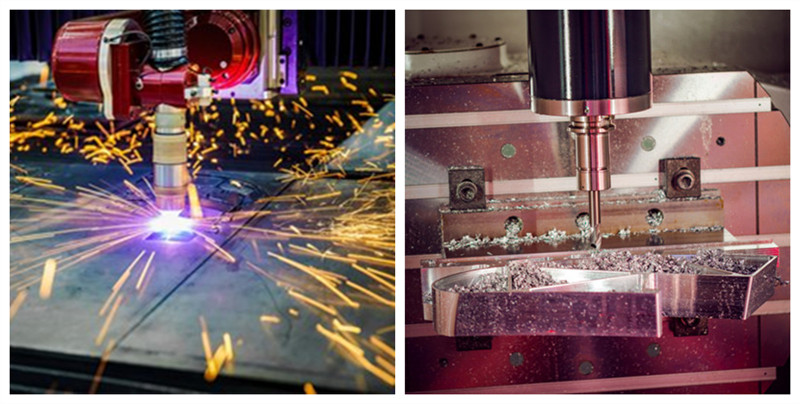

DIFFERENT PRINCIPLES

CNC Routers adopt the mechanical cutting method, which uses high-speed rotating tools for cutting. Laser cut machines use high-energy laser beams to cut the workpiece.

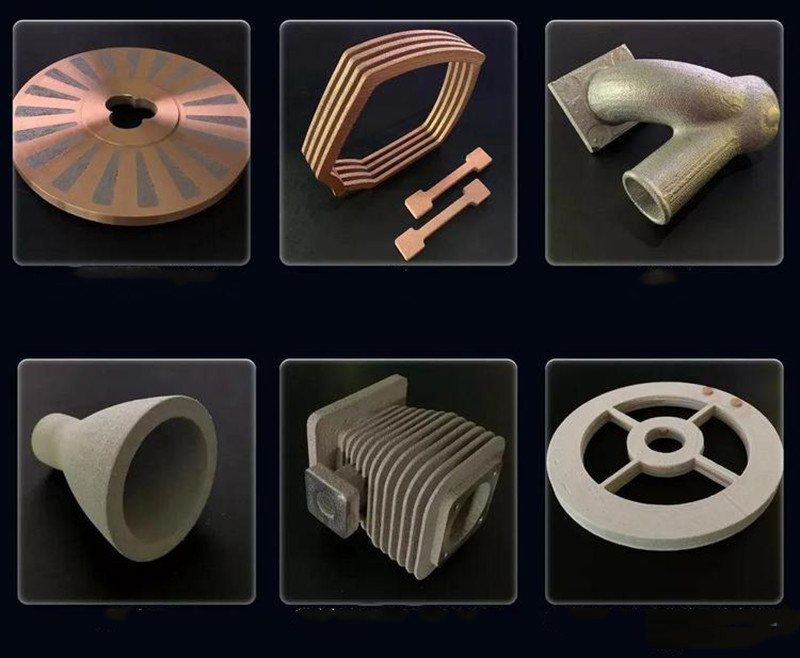

DIFFERENT MATERIALS

CNC Routers are suitable for cutting metal, alloy, steel plate, copper plate, aluminum plate, and other materials. But laser cut machines have a wider cutting range. Laser cut machines can cut metal materials (including carbon steel, stainless steel, silicon steel, galvanized sheet, aluminum alloy, etc.) and non-metal materials (acrylic, plastic, wood board, cloth, etc.).

DIFFERENT CUTTING EFFECTS

The edges cut by CNC Routers are relatively rough. Therefore, the operator needs to carry out subsequent polishing. Laser cut machines are non-contact processing without stress and deformation. The edge cut by laser cut machines is relatively smooth, and no subsequent processing is needed.

DIFFERENT PRECISION

The cutting accuracy of Laser cut machines is relatively high. Generally, it can reach 0.05 mm. The cutting accuracy of CNC Routers is relatively low, generally about 0.1 mm.

DIFFERENT CUTTING SPEEDS

The cutting speed of laser cut machines is faster, which can reach tens of meters per minute. The cutting speed of CNC Routers is relatively slow.

CONCLUSION

In a word, CNC Routers and laser cut machines are common cutting equipment. Laser cut machines are superior to CNC machines in machining speed and accuracy. But in terms of price, the price of laser cut machines is higher. Therefore, the buyer’s choice should be determined according to the actual needs.

If you want to get more information, please don’t hesitate to follow us. Looking forward to hearing from you in the future.