Operation Process of Fiber Laser Cutting Equipment

Posted on 31 Mayıs 2023 Çarşamba

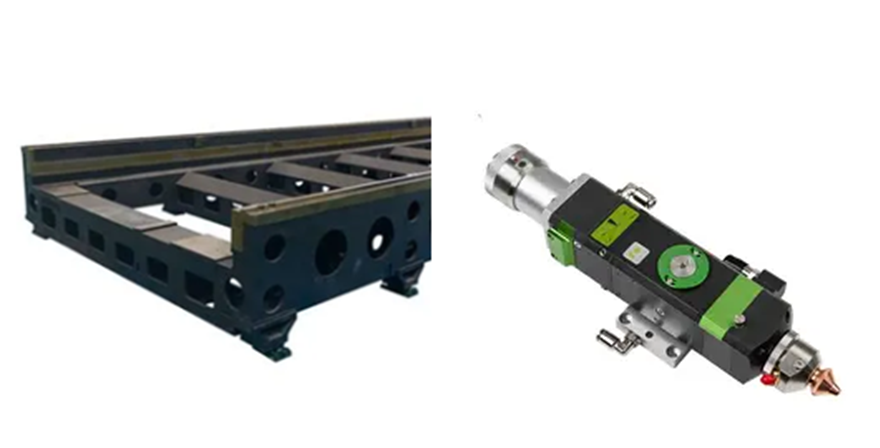

In the past 10 years, fiber laser cutting equipment has undergone tremendous development. Laser cutting machines are highly regarded pieces of equipment in the metalworking industry. Due to its high production efficiency, labor costs are saved. The intelligent fiber optic laser cutting system can conveniently complete various cutting processes. So it is one of the mainstream metal processing equipment today.

OPERATION STEPS OF THE FIBER LASER CUTTING EQUIPMENT

- Determine whether the platform and materials are free of sundries, so as not to damage the fiber laser cutting head during processing.

- Enter the relevant parameters in the operational control system. We should adjust the laser power and laser speed according to the thickness of the material. Moreover, we should also adjust the laser focus and path according to the process requirements.

- Start the cooling system and auxiliary fiber laser cutting gas and check whether the water cooling is completely sealed.

- Start the device and laser. First of all, we need to test the light and proofing. Processing can only begin after passing the test.

SAFETY SPECIFICATIONS FOR FIBER LASER CUTTING EQUIPMENT

- The operator needs to be trained or have corresponding professional knowledge. They must be familiar with laser equipment, operating system, and tool structure, and master laser related knowledge.

- Wear protective equipment as required. When processing highly reflective metals (aluminum, copper, etc.), the operator should wear protective glasses. Doing so avoids damage to eyesight due to metal reflections.

- When using the gas tank, the operator should pay attention to standing on the side of the gas outlet to avoid accidents.

- After the equipment is started, personnel should pay attention to the operation of the equipment and must not leave their posts for a long time. If an unexpected situation occurs, the operator should stop processing in time and turn off the laser.

- Keep the fiber laser cutting head and the surrounding area of the machine tool clean. We need to remove oil and debris to keep the equipment clean.

- When cleaning and maintaining laser equipment, we must strictly followrelevant rules.